A water main is an underground pipe that delivers a steady supply of clean drinking water to service connections (such as residences and businesses). The design of a water distribution system should follow the Master Municipal Construction Documents (MMCD) Standard Specifications and Drawings, the Design Guidelines for Rural Residential Community Water Systems, local Subdivision and Development Servicing Bylaws, as well as regional health authority guidelines for the construction of waterworks.

In BC, a Construction Permit (CP) is required before starting the construction, installation, alteration, or extension of a water main. Emergency repairs do not require a Construction Permit; however, consultation with a Public Health Engineer (PHE) is recommended. The purpose of the CP requirement is to ensure that the design complies with applicable standards and that the public health risk of contaminated distribution systems is reduced.

Design Considerations for Small Water Distribution Systems

The main considerations to keep in mind when considering the design of a distribution network are:

Ensuring flexibility of operation

Minimizing how much of the community is impacted by a water main repair.

Unlike a conventional municipal water distribution system, a small distribution system does not provide water for fire protection. Small distribution systems are sized based on the pressure and flow at the period of peak demand. Special design considerations should be given to pipe sizing, water main looping, separation, and providing enough valves for flow control and flushing.

General Considerations

Water mains should be looped to reduce dead ends, prevent stagnation of water, and minimize service disruption during repairs. If dead ends or low points are present, blow-offs or hydrants should be provided for flushing. For small water systems, “yard-hydrants” are normally used for this purpose.

Shut-off valves are used to isolate reasonably sized sections of the system for repairs or maintenance in order to minimize the number of people and businesses impacted. Shut-off valves are typically located at no more than 150 metre intervals in commercial areas and at no more than 240 metre intervals in other areas. Future expansion and development should be taken into consideration when spacing the isolation valves.

As air pockets can collect at high points in a distribution line, air relief/release valves can be installed to prevent surges or water hammer. To prevent damage from water hammer and protect the pipe, use concrete thrust blocks at valves, bends, tees, reducers, plugs, caps, hydrants, and blow-offs for water mains 100mm (4 in) or larger.

To prevent water pipes from freezing, a minimum 1.8 metres depth of cover is required in BC. Depth of cover can be calculated by the depth of frost penetration or by referring to the depth of successful existing similar water pipes in the area. Measures should be taken to prevent freezing of water mains and services. The system should be pressure tested before use.

Water Main Sizing

Water main sizing is determined by:

- Distribution system modeling (commonly referred to as hydraulic modeling); which uses a mathematical model to predict how a water system will perform

- Cost considerations

- Pressure requirements

- Current and future water demand

In general, distribution lines are required to maintain a minimum pressure of 140 kPa (20.3 psi) at ground level at all points in the system. The minimum pressure of 140kPa (20.3 psi) should be maintained under all flow conditions; this includes Maximum Day Demand (MDD) and critical fire flow conditions (you can find this information and more, in the BC Design Guidelines for Rural Residential Community Water Systems). Pressures below this can allow contaminants to be introduced by the sudden drop in pressure at cross connections. The minimum acceptable water main size is 50 mm (2 in) in diameter, while the minimum acceptable service line is 25 mm (1 in).

Water Main Materials

You should install pipe material and fittings that can withstand all surge and transient pressures, as well as those which conform to the applicable NSF Standards for your system.

It is important to consider the anticipated water quality (corrosiveness, etc.) and bedding soil characteristics when choosing the pipe material and fittings. Both metal and plastic pipe can be used in the construction of water mains. Common materials include:

- Ductile Iron and Steel

- Polyvinyl chloride (PVC)

- Polyethylene/High-Density Polyethylene (PE or HDPE)

- Concrete Pressure Pipe

Cross Connections

A cross connection is any connection (or potential connection) between any part of a drinking water system and any other environment. These need to be carefully avoided as they allow contamination substances to enter the potable water system.

It is prohibited to have cross connections with any sanitary or storm sewer or other source of non-potable water. To avoid this, your distribution system must not connect with items such as irrigation hydrants, sump pumps, or chemicals such as pesticide solution tanks, as these could permit the entrance of contaminants into the system.

Separation from Contamination Sources

The water main should be designed and constructed away from any contamination sources. Consider the following factors in providing adequate separation:

- Materials, type of joints and joint sealants for water and sewer pipes

- Soil conditions

- Water service and branch connections into the water main

- Sewer line locations and branch connections

- Compensating variations in the horizontal and vertical separation

- Space for repair and alterations of water and sewer pipes

- Off-setting of pipes around manholes

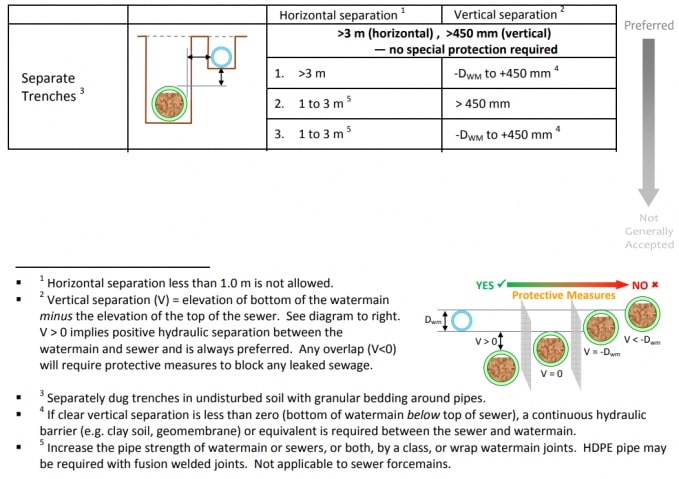

Separation Requirements Between Water Main and Sewer Pipes

To avoid possible contamination, you must maintain a specified minimum vertical and horizontal distance between water mains and sewer pipes. New works must follow current best construction practices, while existing works may remain as is with the consent of the Public Health Engineer (PHE).

A water main should be laid at least 3 meters (10 feet) horizontally from any sanitary or storm sewer line. Where this horizontal separation is not possible, and/or where water mains and sewer lines must cross or share the same trench, the water main should be at least 0.45 m (1.5 feet) above the sewer (measured between the bottom of the watermain and top of the sewer line). It must also be sufficiently placed to one side of the sewer to allow for sewer repairs without disturbing the water main. In addition, a water pipe must not pass through or come in contact with any part of a sewer manhole.

If a variance in this separation is proposed, the water system designer must provide written reasons to the PHE as to why this is necessary (such as bedrock or existing utilities in limited space) as well as outlining the additional protective measures that will be implemented to reduce health risks. Those additional protective measures may include a higher pressure class pipe, a joint and/or structural protection and/or casing the water or sewer line.

If neither the horizontal or vertical separation is possible then the sewers should be of the same service capability (same pipe material) as the water main, and should be designed to withstand high groundwater table conditions without damage to joint seals (this also applies to water mains when depressurized).

Preferably, you should have a 7.6m (25 feet) setback between the water main and septic tanks, waste stabilization ponds, open sewage discharge locations or any other point source of contamination. If this is not possible, the minimum allowable distance is a 3 meter (10 ft) setback. Under no circumstances should a water line extend through a septic tank, sewage disposal field, sewage lagoon or feedlot.

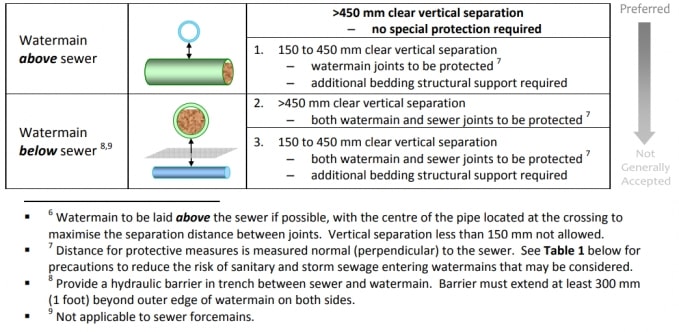

Crossings of water main and sewer line:

Where a water main crosses a sanitary or storm sewer, the water main should be laid to provide a minimum vertical distance of 0.45 metres (1.5 feet) between the outside of the water main and the outside of the sewer. Best practice is for the water main to be above the sewer. At crossings, the water main joints should be as far as possible from the sewer line and sewer joints. It is important that when the mains and pipes are laid, there is one full length of water pipe at the crossing. This means that both joints will be as far from the sewer pipe as possible. Special structural support for the water and sewer pipes may be required. If conflicts occur, provide additional protective measures.

In situations where water mains must cross under sewers, at least 0.45 m (1.5 feet) clear vertical separation should be provided (measured between the outside of the water main and the outside of the sewer) and construction details need to be provided to the PHE. Where possible, the above separation practices should also be applied to water service connections.

Water main valves should be provided to isolate reasonably sized sections of the system for repair or maintenance. It is recommended that they be placed on property line projections if possible, to make them easier to locate.

To assist water system designers, Northern Health has prepared a document entitled “Public Health Engineering Guidelines Sewer ‐ Watermain Conflicts” that includes Diagram 1 shown below.

Disinfection of Water Mains

Water mains must be disinfected after construction, alteration, extension, or repair. They must be proven to be bacteriologically safe prior to operation. Disinfection should follow the most current version of C651-92 American Water Works Association (AWWA) Standard of Disinfecting Water Mains, which offers options for rapid disinfection. Bacteriological samples must be sent to an accredited lab to confirm the water is safe. The BC Provincial Health Officer (PHO) approves laboratories for the microbiological testing of drinking water. The BC Centre for Disease Control Public Health Laboratory has a link to the most current “PHO Approved Laboratory List” (accredited labs). Laboratories registered with the Canadian Association for Laboratory Accreditation (CALA) are accredited to test chemical parameters.

After disinfection, the chlorinated water in the pipeline should be completely removed by thorough flushing. If there is no sanitary sewer manhole to dispose of the chlorinated water, the water must be dechlorinated with sodium thiosulphate before discharging it. It must be discharged to the approved outlet or to the environment; not to any ditches, ravines, surface water sources, or wells. The new water mains should be isolated by physically separating them from the existing water distribution system until acceptable bacteriological testing is approved by the local Drinking Water Officer.

Master Municipal Construction Documents Association (2009 and subsequent editions) - provides details on the construction of waterworks systems (including water mains).

M14 Backflow Prevention and Cross-Connection Control: Recommended Practices, Fourth Edition, Manual of Water Supply Practices, AWWA, 2015 - provides information on cross connections, and the types of backflow prevention devices required to prevent contamination of drinking water.

Public Health Engineering Guidelines Sewer ‐ Watermain Conflicts, Northern Health, 2012 - discusses the horizontal and vertical separation requirements between water mains and sewer mains needed to prevent contamination of drinking water.

C651-92 American Water Works Association (AWWA) Standard for Disinfecting Water Mains - essential procedures for disinfecting new and repaired water mains.

The following three references relate to distribution system modeling (commonly referred to as hydraulic modeling) which uses a mathematical model to predict how a water system will perform. This is important in determining the design of water main networks and the sizing of the water mains:

- M32 Computer Modeling of Water Distribution Systems, Fourth Edition, Manual of Water Supply Practices, AWWA, 2017

- Engineering Modeling Applications, web page re hydraulic modeling, AWWA

- EPANET Application for Modeling Drinking Water Distribution Systems, US EPA

American Water Works Association (AWWA) standards

National Sanitation Foundation (NSF) standards

The BC Design Guidelines for Rural Residential Community Water Systems (2012)

Guidelines for the Construction of Waterworks, Interior Health, June 2014

Emergency repairs are discussed in Section 6(3)(a) of the Drinking Water Protection Regulation